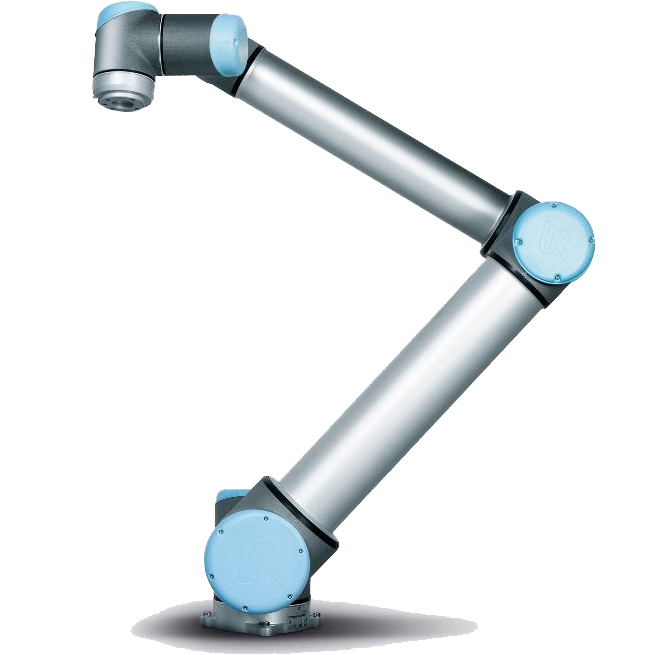

Deliver high quality products – every time

Robots offer considerable benefits to the furniture and equipment industry along the production process and the quality of the fabricated product. A collaborative robot arm delivers impressive levels of precision and consistency while reducing your margin of error. There are even more efficiency and quality benefits associated with the implementation of robot arms in the industry producing furniture:

• The production process of furnishings is often still manual work – flexible deployment of the robot arm to produce individual products like furniture is key. Moving the robot arm to new processes is fast and easy and is giving you the agility to automate almost any manual task.

• Production and distribution of furniture and equipment is labor-intensive, tedious and physically stressful. Material handling of heavy furniture is one of the main robotic applications to avoid physical burdens for the workers.

• The results are more consistent products. This also means improving the fit and finish of your goods while increasing productivity across the production line.

Robots take a seat in the furniture industry

Robots can be used in many aspects of building material production, including: bonding, placing, mixing, packaging, all types of welding, palletizing, packaging, and much more. A robot will always use exact measurements when mixing ingredients and is extremely precise with cutting and joining of materials. A robot arm does not lift or carry the same way an employee does, reducing the risk of RSI and other ailments brought about by demanding work roles.

Contact us today to find out how we can help you implement robotics into your business accomplishing tasks with high endurance, speed and precision. John Henry Foster’s goal of providing innovative and state-of-the-art products continues to expand and now includes a range of industrial robots. Our team of experts are positioned to support your productivity and efficiency needs with this versatile product. Please contact us today at 651.452.8452 or

email us to learn more about this or any of our product offerings.